TIRE PRESSURE SYSTEM TROUBLESHOOTING & DISPLAY MESSAGES

The Sensor/Transmitters are not internally serviceable. If a single Sensor/Transmitter fails and cannot be detected by the EVIC, it must be replaced. Replacement is also required when a "Battery Low" message is displayed. Estimated battery life is 7-10 years.

There are four conditions which will cause a Tire Pressure Monitoring System fault to be set. All fault codes are associated with a specific wheel

location.

1. If the EVIC detects a non-transmitting Sensor/ Transmitter in a road wheel for ten consecutive minutes with vehicle speed above 25 MPH:

A. An active fault code will be stored

B. A Chime is requested

C. "TIRE SENSOR BAD / MISSING" or "SERVICE TIRE PRESSURE SYSTEM" will be displayed

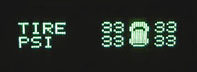

D. A dashed line at the wheel location on the graphic display will be seen if the display is activated.

2. A low pressure sensor battery status

3. All five sensors are transmitting at a shorter than expected interval

4. No valid pressure sensor ID from the spare tire for 20 consecutive ignition cycles spaced at least one hour apart:

A. An active fault code will be stored

B. A Chime is requested

C. "TIRE SENSOR BAD / MISSING" or "SERVICE TIRE PRESSURE SYSTEM" will be displayed.

Use the DRBIII® Input/Output function to further isolate the specific concern. The DRBIII® can be queried to determine the Sensor/Transmitter status:

"Invalid Pressure" - The Sensor/Transmitter is reporting a negative pressure or a pressure above 63 psi.

"Low Batt" - The Sensor/Transmitter has reported a low battery status for seven consecutive ignition cycles.

"Trained" - The Sensor/Transmitter ID code is recognized by the EVIC.

"Active" - The vehicle is moving at 25mph and/or the Sensor/Transmitter is "awake" and transmitting as expected by the EVIC.

SPARE WHEEL AUTO-LOCATE (5-TIRE TPM SYSTEM ONLY)

If the spare tire is mounted on the vehicle, the EVIC will detect the move and determine from the sensor transmit intervals, which wheels are mounted and which one is now the spare. The spare tire sensor/transmitter transmits once per hour. The sensor/transmitters in the mounted wheels transmit once per minute when the vehicle is moving at 25 mph.

"REMOVE MAGNET FROM SPARE" (5-TIRE TPM SYSTEM ONLY)

A magnet is used to initiate a sensor ID transmission. In the EVIC training procedure, the spare wheel is the last in the sequence. If the magnet is left on the wheel, the sensor/transmitter will continue its ID transmission. If the EVIC detects 20 transmissions from the spare wheel in 60 seconds and the vehicle speed is above 40 km/h (25 mph), it will:

A. Request a chime

B. Display "REMOVE MAGNET FROM SPARE" for 60 seconds per ignition-ON cycle

"TIRE PRESSURE UNAVAILABLE"

The EVIC can detect high radio noise interference. When the noise level is too high to distinguish a transmission from a sensor/transmitter, it will:

A. Display "TIRE PRESSURE UNAVAILABLE" for 5 seconds

B. Request a chime

C. Switch back to the previous screen

"TIRE PRESSURE NOW AVAILABLE"

If the "TIRE PRESSURE UNAVAILABLE" message was displayed because of radio noise interference, the EVIC will:

A. Display "TIRE PRESSURE NOW AVAILABLE" for 5 seconds

B. Request a chime when the noise level no longer interferes with sensor/transmitter transmissions

Further technical, diagnostic and safety information can be found in the Factory Service Manual.

PERSISTANT LOW TIRE PRESSURE WARNINGS

After the vehicle has set for 3 hours, check the tire pressures with an accurate pressure gauge and adjust pressures to the door placard pressure specfication and verify using accurate pressure gauge.

DO NOT USE THE EVIC DISPLAYED TIRE PRESSURE VALUES AS THESE MAY NOT REPRESENT THE UPDATED PRESSURE VALUE (Note: The EVIC will not update immediately. In order for the EVIC to update with the new tire pressures you must do one of two things: (1) Wait 15 minutes for the EVIC to update. This is because the TPMS sensors only measure the pressure in the tires during stationary mode every 15 minutes. Stationary mode is reached 15 minutes after the vehicle is parked. (2) Take a quick drive (must go over 20MPH for at least 5 seconds) to prompt the sensors to measure the pressures and therefore update the EVIC with the new pressures. During drive mode, the TPMS sensors check the pressure every 30 seconds).

If the warning still persists, calibrate TPMS sensors (note that after training is completed, the training magnet must be removed from the valve stem or the TPMS sensor battery will become discharged). If the warning still persists the sensor(s) may need to be replaced.

New SmarTire / Cycloid AutoPump system

A tire pump inside each wheel cap!

Inertia compressor pump, internal circuit board, and pump shown mounted inside wheel cap.

|

A new advanced tire pressure monitor system from SmarTire has been tested on some prototype Jeeps. This system or one similar may appear on future models. In conjunction with an automatic tire AutoPump made by Cycloid, this combined system automatically and continously re-inflates tire pressure to a specified level, ensuring optimal inflation of tires under different situations and temperatures.

The inertia compressor is only 1" thick by 3" in diameter and weights a mere 8 ounces. Its expected design life is 130,000 miles, with ten years of battery power. The system has been shown at some past auto shows in the U.S., installed in the Grand Cherokee Concierge prototype concept car.

|